How the Philippines is Making Every Fabric Count in the Fight Against Textile Waste

By: Reina Rose B. Realino

Technology Transfer, Information, and Promotion Staff

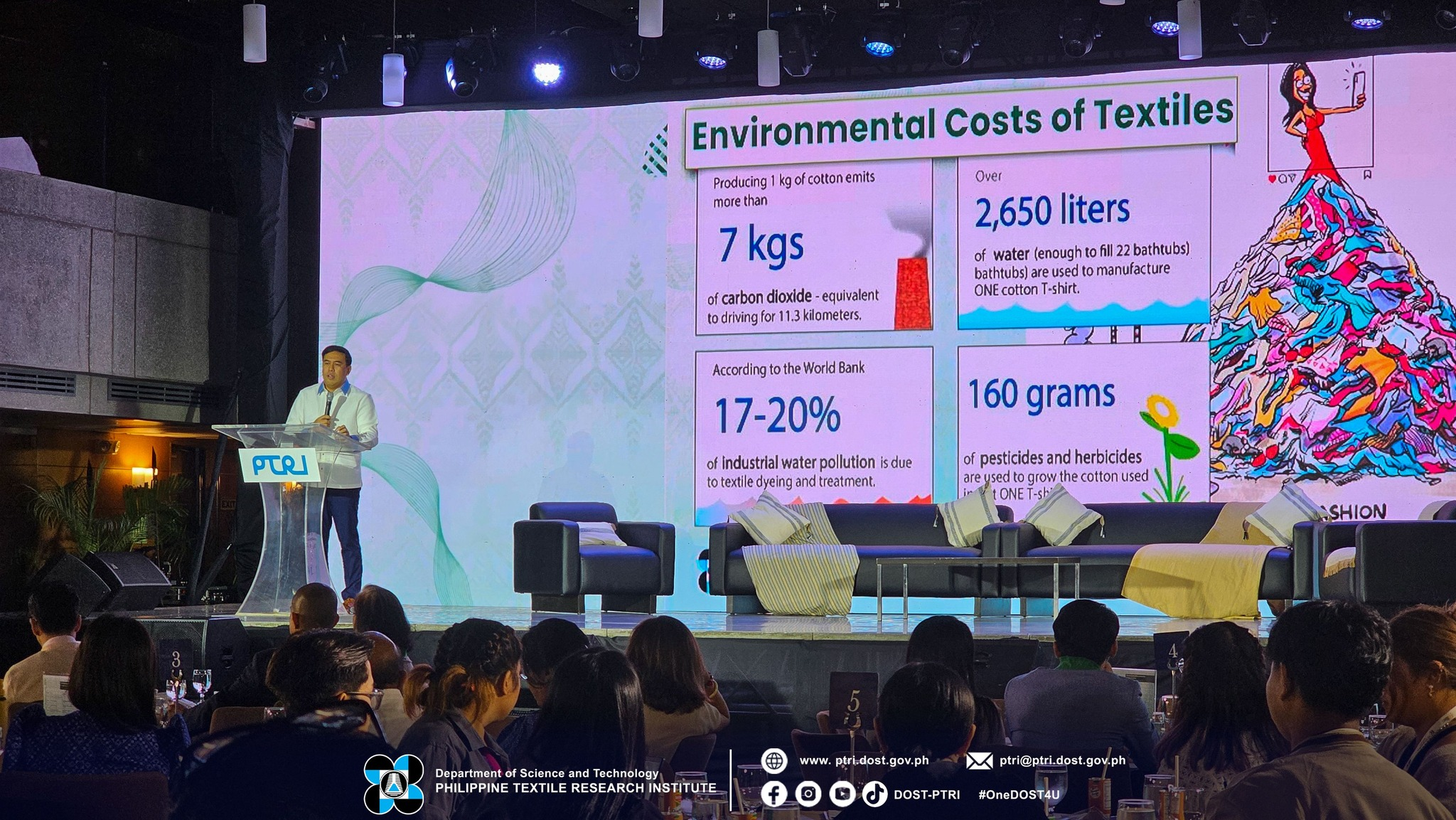

The Growing Crisis of Textile Waste

The fashion industry is one of the largest contributors to environmental pollution and the textile waste primarily ends up in landfills or incinerators, significantly impacting ecosystems and contributing to climate change. In the Philippines, textile waste from manufacturing and post-production processes continues to accumulate, contributing to environmental degradation and resource depletion.

Bayo Manila Inc., a leading local clothing brand, produces around 16 tons of textile waste each year. Without a proper recycling system, much of this waste remains unused, representing both an environmental challenge and an economic loss. As DOST-PTRI Director Dr. Julius L. Leano, Jr. highlighted during the National Textile Convention "There are enough clothes on the planet right now, enough to dress six generations of the human race. Now, textile production has gone up as well, from 58 million tons in 2000 to about 109 million tons in 2020, and is projected to grow to 145 million tons by 2030. So, again, it's not just about production... I’m building the point because we’re going toward asking everyone as well to shift not just our way of producing but our way of consuming."

To address this issue, the Department of Science and Technology-Philippine Textile Research Institute in collaboration with Bayo Manila Inc. through DOST’s CRADLE Program is launching the Textile Revitalized (TexRev) Project which aims to convert post-industrial textile waste into sustainable yarns, providing a viable alternative to virgin textiles.

The TexRev Process: How Fabric Waste Becomes Yarn

The TexRev process starts by collecting and sorting textile waste by color and material type. The fabrics are cut, shredded into fibers, and tested for quality. After removing impurities through carding, the fibers are spun into yarn, blended with virgin materials, and tested for strength and durability. The yarns are converted into fabric, and then undergo finishing treatments like dyeing, water repellency, and antimicrobial coating for sustainable fashion and home textiles.

A Step Toward a Circular Textile Economy

TexRev is more than just a recycling initiative. It is an essential step toward a circular economy, where waste is repurposed into valuable resources. The project helps reduce textile waste and landfill accumulation, alleviating the environmental burden caused by discarded fabrics. It also minimizes water and energy consumption compared to traditional virgin fiber production, making it a more sustainable alternative. TexRev provides fashion and other textile brands with a responsible option, allowing them to move away from conventional textiles and embrace a more sustainable approach to manufacturing.

As Bayo Co-CEO Anna Lagon stated "Through our commitment to the UN Global Compact or the UNGC and collaborations with PTRI, we are proving that a homegrown Filipino fashion brand can be a leader in circular fashion, making an impact both locally and globally. We believe that the future of fashion is truly circular."

By integrating TexRev yarns into their production, manufacturers can lower their environmental footprint while maintaining product quality. Consumers, in turn, can make more sustainable choices by supporting brands that prioritize circular fashion practices.

The TexRev project represents a shift in the textile industry, proving that waste can be transformed into new opportunities. As sustainable solutions continue to gain traction, innovations like this pave the way for a future where fashion and environmental responsibility go hand in hand.

For more information about TexRev and DOST-PTRI’s programs, technologies, and services, the Institute may be reached through email at This email address is being protected from spambots. You need JavaScript enabled to view it. and its official social media accounts.